We want to estimate the growth curve for the purpose of:

1. Having some hard data proving that our material actually promotes growth

2. Estimating the growth curve on our belt design to determine optimal frequency of harvesting

This test being done in Illinois as well as Belize is helpful because Illinois testing will serve as a template for Belize testing: we can modify test design based on what did or did not work, and have an estimate of what the curve will look like (i.e. how long the exponential phase of growh is in comparison to the stationary phase). It will also be interesting to compare how the apparatus will grow algae in different environments.

(Typical growth curve for Tetraselmis suecica.We expect a similarly shaped curve, but our scaling will be slightly different. Source:http://www.fao.org/docrep/007/y5720e/y5720e08.htm)

Some basics about the test:

Algae harvest will be done using a single nail brush, not a harvesting mechanism (why? 1. our belt design was ready before the harvester is ready, 2. we don't want to be able to attribute error to inconsistency in harvest. this is a growth test, not a system test)

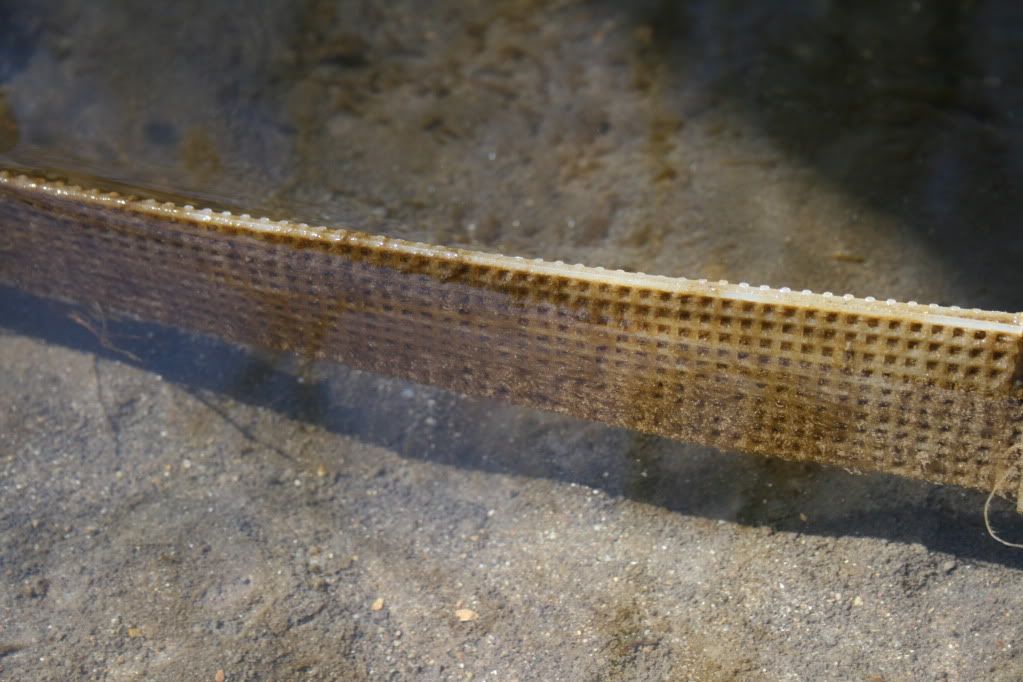

The data we aim for is actually a graph [img]. We'll be plotting grams of dry mass per square centimeters of belt against elapsed time (since last harvest) . Collection will occur at two day intervals at roughly the same time (in the morning). We divide the belt up into ten sections from which we harvest at scheduled intervals (so that our data will be spread out evenly).

Testing time is continuous. Although we will have the minimum useful data set by April 16th, we plan to either continue testing or launch a new round of testing using the harvester we eventually plan to implement.

At each harvest time:

0. Weigh watch glasses

1. Collect from the sections appointed for the day using a nail brush. Collect entire wet mass in a watch glass. Record having harvested.

2. Situation 1: We are allowed to bring home electronic balance. We allow the wet mass to sun dry, and if that isn't possible, we bake the material. Either way, we end up with dry material, and measure the mass (subtracting the watch glass weight). Situation 2: We (carefully) bring the watch glasses into school, bake in the oven in the chem room, and measure dry mass (subtracting the watch glass weight).

3. Record on paper and excel. The excel document will create the graph.

Flaws:

This data is only useful for static water (as opposed to implementation near the control section with accelerated mass collection).

Imprecise. Continuous testing is impossible, human error unlikely but possible (inconsistent harvesting?)