The pond looks terrific and should be a terrific place to trap sediments and test the Aquamats. Thank you Adolpho!

Then Adrian and Wilbur and I loaded up 75 Aquamats (you can get an idea from this photo about the size of 75 mats) and took them down to the pond...

...where we will be using 3 types of Aquamats. The specifications for each type are listed in an earlier post. Capped PVC pipes were inserted through the sleeve at one end. The blue Aquamats with narrow strips float, the green Aquamats with thicker strips float, and white ones with heavy thick strips sink. We have plenty of all three types. The PVC for the floating type will need to be weighted with sand to sink the sleeve and allow the strips to float up from the bottom.

...where we will be using 3 types of Aquamats. The specifications for each type are listed in an earlier post. Capped PVC pipes were inserted through the sleeve at one end. The blue Aquamats with narrow strips float, the green Aquamats with thicker strips float, and white ones with heavy thick strips sink. We have plenty of all three types. The PVC for the floating type will need to be weighted with sand to sink the sleeve and allow the strips to float up from the bottom.

The excavator has been hard at work at Aqua Mar shrimp farm removing old sediment from the sedimentation pond.

The excavator has been hard at work at Aqua Mar shrimp farm removing old sediment from the sedimentation pond.

Progress!!

Vinyl progress: not as much growth as the screens, but stays lightweight and the smooth surface makes it easy to remove material.

Vinyl progress: not as much growth as the screens, but stays lightweight and the smooth surface makes it easy to remove material.

Rubber comes dead last in terms of growth. Material (dirt?) comes off just by touching. But its close neighbor, the steel screen, wins the prize.

Rubber comes dead last in terms of growth. Material (dirt?) comes off just by touching. But its close neighbor, the steel screen, wins the prize.

One of those farms is allowing us to use their AquaMats for the substrate experiments this spring. For anyone who is wondering, here is a shot of the AquMats we'll be using to test the substrate mitigations this spring. As you can see, there's no lack of material here. Your experiments are starting on a small scale (as is appropriate), but when they are fully developed you'll be dealing with quantities of material like this.

One of those farms is allowing us to use their AquaMats for the substrate experiments this spring. For anyone who is wondering, here is a shot of the AquMats we'll be using to test the substrate mitigations this spring. As you can see, there's no lack of material here. Your experiments are starting on a small scale (as is appropriate), but when they are fully developed you'll be dealing with quantities of material like this.

And the plantings from August at Royal Maya are growing to impressive sizes, with 4 internodes already in place and side-branching beginning. When these trees are fully grown, they will be an important part of the mitigation process in the farm effluent.

E. Russell and E. Fritzsche mentioned easy access to ponds. We would probably want to begin testing soon. Mr. Smith mentioned that this time of year may be the best time to test due to the lack of tree leaves that would block out the sun, ensuring similar growing conditions as those in Belize. Also, there is little movement in the water and not too much rainfall. Our goal is to have some test results by the end of spring break.

InvenTeams is also an option. Applications submitted by March 20th will be given early feedback. The initial application deadline is April 24th. If we are to do this, we will have to work very quickly. More information is available at their website.

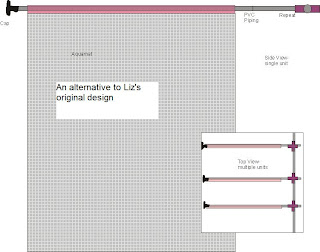

It has many positive qualities and works as an excellent starting point (thanks, Liz!)

It has many positive qualities and works as an excellent starting point (thanks, Liz!)

Main Structure.

Working from this design, I created a similar structure. This design consists of a less sturdy structure, as I use the PVC piping primarily to keep the aquamats from moving and to allow for easy removal of aquamats for replacement. According to http://www.nurturetech.net/aqua.htm, aquamats are equipped with ballast bags to keep them in place, but the PVC structure could allow several aquamats to be removed from the pond at the same time. This structure, consisting of a primary pipe paralleling the side of the effluent canal and perpendicular secondary pipes that the aquamats slip over, is attached to bank of the canal by ropes. One end of a rope would be tied to the primary pipe, and the other end would be tied on a stake on the side of the canal. This means the entire structure can be removed.

Details.

Each unit stemming from the primary pipe is connected by a tee and consists of one PVC pipe, one aquamat, and one cap. The PVC pipe length is slightly longer than the top of the aquamat. For the present, my idea for attaching the aquamat to the pipe would be to fold the top over to create a tunnel. I still need to work out exactly how this could be done, one option would be to sew this pocket in the aquamat; another option would be to use some kind of adhesive or pin to secure this tunnel. The aquamat would be kept from sliding off the PVC pipe by the cap. The top of each unit will be roughly equal to the surface of the water because of the floatation element associated with the aquamat.

Removal of substrate.

This design offers several different options for removal of organisms. I will briefly outline a few of them (discussed in our latest inventor’s club), and eventually follow up with more details.

1. Remove the entire structure and place in shrimp pond. Pros: this way we can utilize organisms growing both on the aquamats and the primary pipe. Cons: time must be allowed for the shrimp to eat off the structure

2. Remove entire structure and strip organisms by hose or rake. Pros: allows for faster cycle than in option 1. Cons: labor

3. Remove aquamats only and strip organisms by hose or rake.

4. (Inspired by Mr. Smith) Leave entire structure in the water, and move down the middle of the canal scraping all of the aquamats in sort of one swoop (this would only work with careful spacing of the aquamats, and we would have to develop a way to collect the substrates in the water). Pros: quick and dirty, Cons: we need to look into this further to be more specific. Hard to describe, so included a brief video demo- the spatula with basket represents the scraper tool (more on that later), the sticky notes are aquamats.

Pictures

Apologies for the strange model. PVC pipes represented by chopsticks, caps by pencil toppers, aquamats by cut paper, water by blue towel, rope by red yarn, PVC tees by masking tape.

http://i710.photobucket.com/albums/ww101/theodore1800/design1v2.jpg